一、自备应急和备用柴油发电机组的机房设计:

1、机房宜布置在建筑的首层、地下室、裙房屋面。当地下室为三层及以上时,不宜设置在最底层,并靠近变电所设置。

机房宜靠建筑外墙布置,应有通风、防潮、机组的排烟、消声和减振等措施并满足环保要求。

2、机房宜设有发电机间、控制室及配电室、储油间、备品备件储藏间等。当发电机组单机容量不大于1000kW或总容量不大于1200kW时,发电机间、控制室及配电室可合并设置在同一房间。

3、机组容量与台数应根据应急或备用负荷大小以及单台电动机最大启动容量等综合因素确定。当应急或备用负荷较大时,可采用多机并列运行,应急柴油发电机组并机台数不宜超过4台,备用柴油发电机组并机台数不宜超过7台。额定电压为230V/400V的机组并机后总容量不宜超过3000kW。当受并机条件限制时,可实施分区供电。

4、机房面积在50m?及以下时宜设置不少于一个出入口,在机房面积50m?或者长度7米以上时宜设置不少于两个出入口其中一个应满足搬运机组的需要;发电机间与控制室、配电室之间的门和观察窗应采取防火、隔声措施,门应为甲级防火门并应开向发电机间。

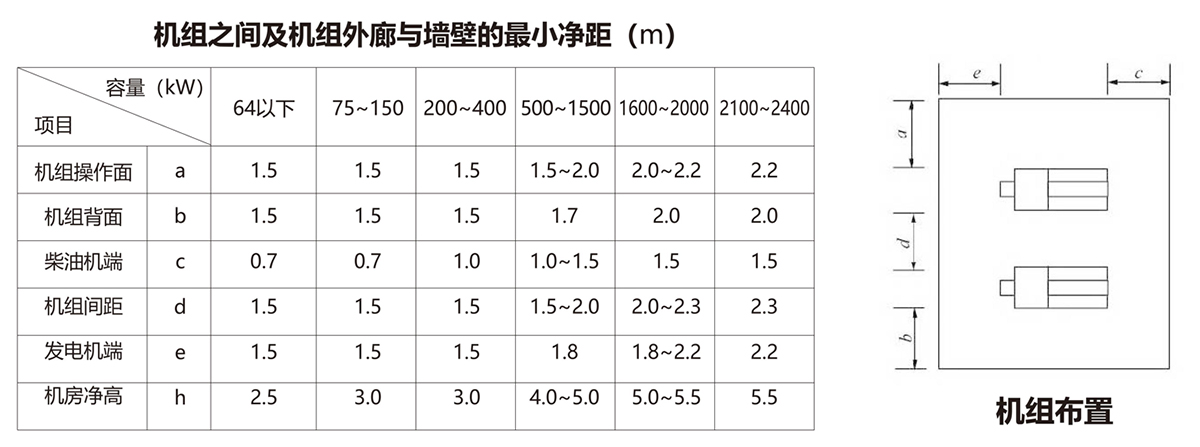

5、机房设备布置应符合机组运行工艺要求:1)机组宜横向布置;2)机房与控制室、配电室贴邻布置时,发电机出线端与电缆沟宜布置在靠控制室、配电室侧;3)机组之间、机组外廊至墙的净距应满足设备运输、就地操作、维护检修或布置附属设备的需要.

注:当机组按水冷却方式设计时,柴油机端距离可适当缩小;当机组需要做消声工程时,尺寸应另外考虑。

二、机房进、排(热)风口的设计:

1.机房进风,口宜设在正对发电机端或发电机端两侧,进风口面积不宜小于柴油机散热器面积的1.6倍;自然进风面积应该大于出风口面积的1.25倍。

2.热风,出口宜靠近目正对柴油机散热器; 热风管与柴油机散热器连接处,应采用软接头; 热风出口的面积不宜小于柴油机散热器面积的1.5倍;热风出口不宜设在主导风向一侧,当有困难时,应增设挡风墙。3、当机组设在地下层,热风管无法平直敷设引出时,其热风管弯头不宜超过两处,且应计算风管的阻力损失,

三、特别注意新风量及排烟量的合理配合,以及对环境噪声的影响。

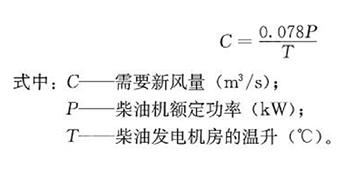

柴油发电机运行时,机房的换气量应等于或大于维持柴油机燃烧所用新风量与维持机房温度所需新风量之和。据国外有关资料介绍,维持机房温度所需新风量可按下式确定:

维持柴油机燃烧所需新风量可向柴油机厂家索取,当海拔增加时,每增加763m,空气量应增加10%。若无资料,可技1kW制动功率需要0.1m3/min估算。

四、机组排烟管的敷设:

1)每台柴油机的排烟管应单独引至排烟道,宜架空敷设,也可敷设在地沟中;排烟管弯头不宜过多,且能自由位移;水平敷设的排烟管至排烟道宜设0.3%~0.5%的坡度,并应在排烟管最低点装排污阀;2)排烟管的室内部分采用架空敷设时,应敷设隔热保护层;3)机组的排烟阴力不应超过柴油机的背压要求,当排烟管较长时,应采用自然补偿段,并加大排烟管直径;当无条件设置自然补偿段时,应装设补偿器;4)排烟管与柴油机排烟口连接处应装设弹性波纹管;5)排烟管过墙应加保护套,伸出屋面时,出口端应加装防雨帽;6)非增压柴油机应在排烟管装设消声器;两台柴油机不应共用一个消声器,消声器应单独固定

五、柴油发电房储油间消防验收的相关规定。

1、柴油发电机房应采用耐火极限不低于2.00h的隔墙和1.50h的楼板与其他部位隔开

2、发电机组散热水箱和排风口之间的软连接要选择耐火等级足够的防火布安装。

3、机房内应设置独立储油间,油箱容量≤1M3,储油量不超过8小时需要量。

4、储油间内要铺上10公分厚的细沙来防渗油,具体高度按照储油间面积和油箱容积计算。

5、油箱上应安装伸向室外的通气管,末端加装呼吸阀(带阻火器),有时还要增加防雨帽。

六、发电机组的自启动与并列运行:

1、用于应急供电的发电机组平时应处于自启动状态。当市电中断时,低压发电机组应在30s内供电,高压发电机组应在60s内供电;

2、机组电源不得与市电并列运行,并应有能防止误并网的联锁装置:

3、当市电恢复正常供电后,应能自动切换至正常电源,机组能自动退出工作,并延时停机

4、为了避免防灾用电设备的电动机同时启动而造成柴油发电机组熄火停机,用电设备应具有不同延时,错开启动时间;

5、重要性相同时,宜先启动容量大的负荷。

七、自启动信号线的接线方式:

1、一般取自市电主开关的辅助触点;

2、从变压器出线端的开关上口拾取电压启动信号;

3、利用开关的PLC可编程控制器送出信号;

4、如果是2台变压器,分别在2台总柜上各装一只中间继电器,它们的常备触点串接发电4机的启动回路,市电停电后,中间继电器的常备触点闭合即可发出启动信号。

5、自启动信号线可以接有源信号或者无源信号,有源信号方便,不用再新拉充电线,信号线规格一般为RVV-2*1.5mm?。

八、机房接地系统:

1、1kV及以下发电机组的中性点工作制应符合下列规定:

1)只有单台机组时,发电机中性点应直接接地,机组的接地形式宜与低压配电系统接地形式一致。

2)当多台机组并列运行时,每台机组的中性点均应经刀开关或接触器接地。

2、3kV~10kV发电机组的接地方式宜采用中性点经低电阻接地或不接地方式;经低电阻接地的系统中,当多台发电机组并列运行时,每台机组均宜配置接地电阻。

3、柴油发电机房接地与通信应符合下列规定:

1)机房内的接地,宜采用共用接地;

2)燃油系统的设备与管道应采取防静电接地措施;

3)控制室与值班室应设通信电话,并应设消防专用电话分机。

服务热线:0757-2225-5425

服务热线:0757-2225-5425